How to repair MIG welding machine? When it comes to repairing your MIG welding machines, it is important to have the right tools and know-how. In this blog post, weldfaq will outline some of the most common welder problems and how to repair MIG welding machine.

Common welder problems

Welding machines are complex pieces of equipment that can experience a variety of problems. Some of the most common issues include:

Power supply problems: Welding machines may experience power supply problems such as surges, voltage fluctuations, or power outages, which can damage the machine or affect the quality of the weld.

Arc instability: Arc instability can cause the arc to wander or become difficult to control, making it harder to achieve a consistent weld.

Machine overheating: Welding machines can become overheated due to a variety of factors, such as high ambient temperature, high-duty cycles, or improper ventilation. Overheating can cause damage to the machine or affect the quality of the weld.

Arc blow: Arc blow is a phenomenon that occurs when the magnetic field generated by the current in the welding electrode interferes with the magnetic field of the workpiece, causing the arc to drift.

Welding cable damage: Welding cables can become damaged due to wear and tear, cuts, or exposure to extreme temperatures, which can affect the electrical performance of the machine and the quality of the weld.

Control problems: Welding machines may experience control problems such as incorrect amperage or voltage settings, which can affect the quality of the weld.

Poor grounding: Poor grounding can cause a variety of problems, such as arc blow, voltage fluctuations, or reduced electrical performance.

How to repair MIG welding machine

Repairing a MIG welding machine can be a complex process, and the steps for repairing it will depend on the specific problem that you are facing. Here are some general steps for repairing MIG welding machines:

1. Identify the problem: The first step in repairing a MIG welding machine is to identify the specific problem you are facing. This may involve troubleshooting the machine and testing its various components to determine what is causing the issue.

2. Consult the manual: Once you have identified the problem, consult the machine’s manual to see if there is any specific advice on how to repair it. The manual may also provide information on recommended parts and tools that you will need.

3. Check the power supply: If you are experiencing power supply problems, such as surges or voltage fluctuations, you may need to check the electrical supply to the machine. This may involve testing the voltage, checking the grounding, or testing the fuses.

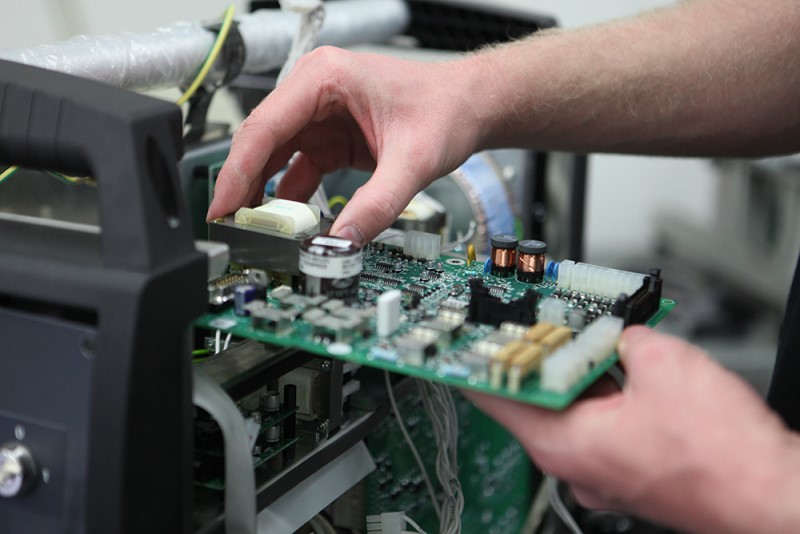

4. Replace damaged components: If you have identified a damaged component, such as a worn or damaged welding cable, you will need to replace it. Make sure to use high-quality parts that are compatible with your machine to ensure that the repair will be effective.

5. Adjust settings: If you are experiencing problems with the arc, such as instability or arc blow, you may need to adjust the machine’s settings to correct the problem. This may involve adjusting the voltage, amperage, or wire feed speed.

6. Clean the machine: Welding machines can become contaminated over time, which can affect the quality of the weld. Clean the machine regularly to remove any debris or contaminants that may be interfering with the welding process.

7. Professional repair: If you are unable to repair the machine on your own, or if the problem is too complex to fix on your own, consider seeking professional repair services. A professional repair service will have the expertise and equipment to diagnose and repair the problem effectively.

Remember, safety should always be the first priority when working on welding equipment. If you are unsure about how to safely repair the machine, or if you are not comfortable working with electrical equipment, it is best to seek professional repair services.

Frequently asked questions (Weld FAQ)

My MIG welder is not feeding wire properly. What could be the issue?

The issue could be with the drive rollers or the liner. Check the drive rollers for any damage or wear, and replace if necessary. If the liner is worn or damaged, it should also be replaced.

How can I clean my MIG welder and keep it in good working condition?

To clean your MIG welder, first, turn off the power and disconnect the welder from the power supply. Clean the exterior of the welder with a damp cloth, and wipe down the interior with a dry cloth. Check the wire feed system and drive rollers for any build-up of debris, and clean if necessary.

How often should I replace the consumables on my MIG welder?

The frequency with which you need to replace the consumables on your MIG welder will depend on how frequently you use it and the type of material you are welding. As a general rule, you should replace the electrode and shielding gas regularly to ensure consistent performance and quality. The liner should also be replaced if it becomes worn or damaged.

Conclusion

If your MIG welder is not working, there are a few things you can do to get it repaired. First, make sure you have the necessary tools and parts to repair it. Next, consult a repair manual or online guides to repair welding machines. Finally, take your machine to a qualified technician.