Welding is a crucial process in various industries, including construction, manufacturing, and automotive. To ensure efficient and high-quality welds, welding machines require specific accessories and parts. These components not only enhance the performance and durability of the equipment but also contribute to the safety and precision of the welding process. In this article, we will delve into the world of welding machine accessories and parts, exploring their functions, types, and benefits.

Welding Machine Accessories and Parts

Welding Machine Accessories

A. Welding Cables and Connectors

Welding cables and connectors are essential accessories that provide the electrical connection between the power source, welding machine, and the welding electrode. They carry the electric current necessary for the welding process. Welding cables are designed to withstand high temperatures and carry heavy currents without overheating. Connectors and adapters ensure secure and reliable connections between the various components of the welding setup.

B. Welding Electrodes

Welding electrodes are consumable accessories used to create the arc necessary for the welding process. They come in various types, including stick electrodes, MIG and TIG welding electrodes, and flux-cored electrodes. Each type is suitable for specific welding applications and materials. Welding electrodes play a crucial role in determining the quality, strength, and durability of the weld.

C. Welding Torch and Consumables

The welding torch is a handheld device that directs the flow of gas and the electrode to the welding area. It is an integral part of MIG, TIG, and other welding processes. Welding torches consist of various components, including gas nozzles, contact tips, and diffusers, which ensure proper shielding gas flow and electrode feeding. These consumables need regular replacement to maintain the performance and precision of the welding process.

D. Welding Helmets and Protective Gear

Welding helmets are essential for welders’ safety and protection. They shield the face and eyes from intense arc light, sparks, and debris. Welding helmets come in two main types: passive welding helmets and auto-darkening welding helmets. Passive helmets have a fixed darkened glass, while auto-darkening helmets feature an electronically controlled lens that automatically darkens when the arc is struck. Additionally, welders require other protective gear such as welding gloves, protective clothing, and respiratory equipment to ensure their safety and well-being.

Welding Machine Parts

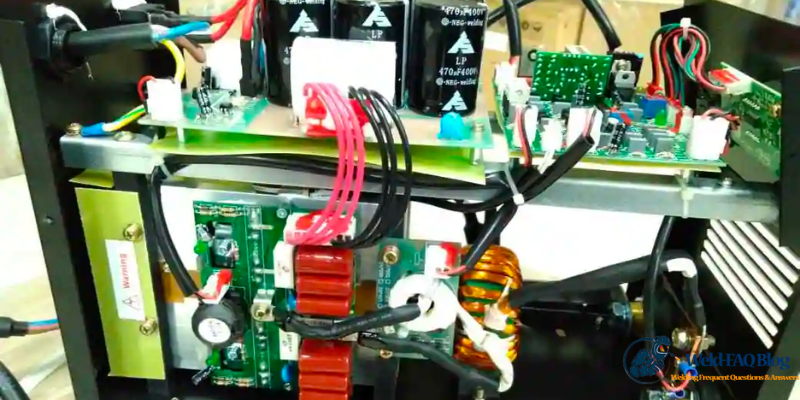

A. Power Source

The power source is a critical component of a welding machine. It provides the necessary electrical power to create and maintain the welding arc. Power sources can be transformer-based or inverter-based. Transformer-based power sources are robust and reliable, suitable for heavy-duty welding applications. Inverter-based power sources are lightweight, portable, and offer advanced control features.

B. Wire Feed Systems

Wire feed systems are used in welding processes such as MIG (Metal Inert Gas) welding. They feed the welding wire continuously into the welding arc, ensuring a steady and consistent weld. Wire feed systems come in different types, including constant voltage (CV) wire feeders, constant speed wire feeders, and synergic wire feeders. Each type offers specific advantages and is suitable for different welding applications.

C. Gas Supply System

The gas supply system is responsible for providing shielding gas to protect the weld from atmospheric contamination. It consists of gas cylinders, regulators, flowmeters, and hoses. Gas cylinders store the shielding gas, while regulators and flowmeters control and monitor the gas flow. Proper gas supply is crucial for achieving clean and high-quality welds.

D. Cooling Systems

Welding machines generate heat during operation, which can affect their performance and longevity. Cooling systems help dissipate this heat and maintain optimal operating temperatures. There are two main types of cooling systems: air-cooled systems and water-cooled systems. Air-cooled systems rely on fans and heat sinks to dissipate heat, making them simpler and more cost-effective. They are suitable for light to moderate welding applications. Water-cooled systems, on the other hand, utilize a water circulation system to remove heat from the welding machine. They are more efficient and ideal for heavy-duty welding operations that generate significant heat.

Cooling units, such as water coolers or air coolers, are integral parts of water-cooled and air-cooled systems, respectively. These units help maintain the temperature of the welding machine within safe operating limits, preventing overheating and ensuring optimal performance.

E. Control Panels and Interfaces

Control panels and interfaces provide welders with the ability to adjust and regulate various parameters of the welding process. They offer control settings, display important information, and enable the monitoring of welding parameters. Welding machine control panels and interfaces vary in complexity and features, ranging from basic knobs and switches to digital displays with advanced controls.

The control settings on the panel allow welders to adjust parameters such as voltage, amperage, and wire feed speed, depending on the welding process and the material being welded. The display provides real-time information about the welding parameters, allowing welders to monitor and maintain optimal conditions.

Conclusion

Welding machine accessories and parts play a vital role in ensuring the efficiency, quality, and safety of the welding process. Welding cables and connectors establish the electrical connection between the power source and the welding electrode. Welding electrodes create the arc necessary for welding and come in different types for various applications. Welding torches and their consumables direct the flow of gas and the electrode, contributing to precise and reliable welds. Welding helmets and protective gear protect welders from the hazards of the welding environment.