In this blog, WeldFAQ will show you the basics of MIG welding and give you some tips to get started. If you’re new to soldering, start by reading our basic MIG welding for beginners tutorial. Once you have a basic understanding of the process, you can start learning about MIG welding. Whether you are a beginner looking to get started, or an experienced welder looking for ways to improve your welding skills, this post is for you.

How to do basic MIG welding for beginners

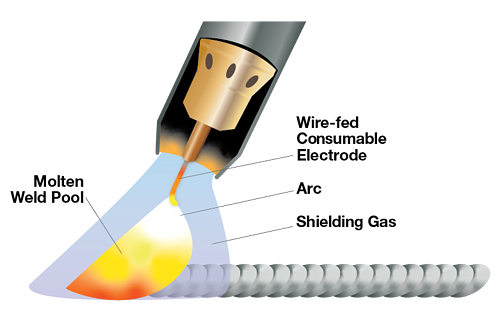

MIG (Metal Inert Gas) welding is a commonly used welding process that involves feeding a wire electrode and shielding gas through a gun to join two metal pieces. Here are the basic steps for MIG welding for beginners:

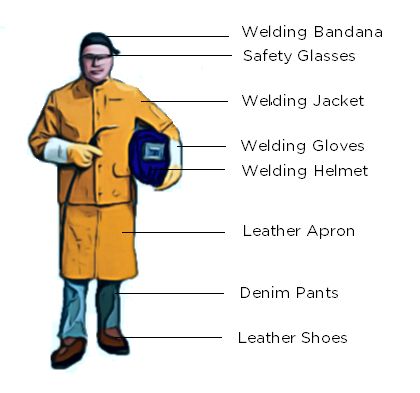

- Gather equipment: MIG welder, welding wire, shielding gas, work clamp and cable, welding helmet, gloves, and protective clothing.

- Set up the welder: Choose the right welding wire and shielding gas for your project, set the welding parameters such as voltage and wire feed speed, and attach the work clamp to the metal piece.

- Prepare the metal: Clean the metal surfaces to be welded to ensure proper adhesion.

- Begin welding: Start the arc by touching the tip of the wire to the metal, then move the gun along the joint in a smooth and consistent motion, making sure to maintain the proper distance from the metal and the angle of the gun.

- Maintain a proper welding position: Keep the gun at a 10-15 degree angle to the metal and maintain a consistent speed to ensure a smooth, even weld.

- End the weld: When you reach the end of the joint, lift the gun to break the arc and stop the wire feed.

The basics of MIG welding equipment

Metal Inert Gas (MIG) welding requires a number of components to create an effective welding setup. Here are the basic components of MIG welding equipment: Power source, Welding gun, Welding wire, Shielding gas, Welding cable, Ground clamp, Chipping hammer, and Protective clothing.

Common MIG welding mistakes

MIG welding can be a simple process, but even experienced welders can make mistakes. Here are some common MIG welding mistakes to watch out for:

- Excessive welding speed: Welding too fast can cause the metal to overheat and cause warping or burn-through.

- Improper shielding gas: Using the wrong shielding gas or not enough of it can result in porosity and a weak weld.

- Dirty or damaged MIG gun: A dirty or damaged MIG gun can cause the wire to break, which can stop the weld, or result in poor weld quality.

- Poor joint preparation: A dirty or oily surface can weaken the weld, so it’s important to clean the metal before welding.

- Inconsistent wire feed: An inconsistent wire feed can cause uneven heat input and affect the quality of the weld.

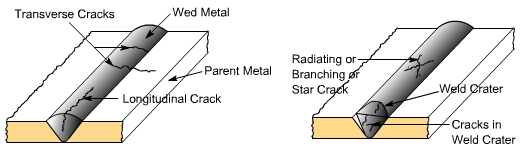

- Poor weld bead appearance: Improper technique or incorrect welding parameters can result in a weld bead that’s too wide, has too much spatter, or has a porous appearance.

- Incorrect electrode angle: Holding the electrode at the wrong angle can result in poor weld quality, porosity, and burn-through.

It’s important to be aware of these common MIG welding mistakes and to make adjustments as necessary to ensure a successful weld. Regular practice and proper training can help prevent mistakes and improve your welding skills.

MIG welding safety

MIG welding can be a safe process if proper safety measures are taken. Welding can produce intense light and heat, so it’s important to wear a welding helmet with a proper lens shade, gloves, long sleeves, and pants made of fire-resistant material.

Welding produces fumes and gases that can be hazardous, so it’s important to provide proper ventilation or use a respirator. Make sure the workpiece is securely clamped to prevent it from moving while welding, and make sure the welder is properly grounded to prevent electrical shock.

Welding can produce sparks that can ignite flammable materials, so it’s important to keep them away from the work area. Before starting to weld, inspect the MIG welder, gun, and cables to make sure they’re in good condition.Store welding supplies, including welding wire and shielding gas, in a safe place to prevent accidents.

Welding can be hazardous if done for long periods, so take breaks and rotate with other workers if necessary. By following these safety tips, you can reduce the risk of injury while MIG welding and ensure a successful and safe welding experience.

Bottom Line

Above is basic MIG welding for beginners which can help you to gain more knowledge of MIG welding. It’s important to follow all safety precautions while welding, such as wearing protective clothing and a welding helmet, and properly ventilating the work area. Also, it’s recommended to receive proper training and practice before attempting to weld on your own.

We hope that this guide has helped you get started with MIG welding. If you have any questions, don’t hesitate to contact us.