As a welder, you not only have a welding machine, but you also need a lot of the necessary tools and accessories to go with it. There are many of them, but you need to know which ones are must-haves and which ones are useful. Welcome to ‘13 Must-Have Welding Tools and Accessories for Beginner‘, we‘ll share a bit of useful information for you!

Why are welding tools and accessories necessary?

Any welding project should begin with safety as its first priority. If you don’t initially safeguard yourself, you won’t be able to weld with the best outcomes. When performing your job, protective attire, safety equipment, and accessories are essential.

Seamless metal joining is not possible without tools. You must correctly prepare the metal in order to guarantee a neat and sturdy weld. To prevent movement, you must also ensure that the metal is firmly in place before you begin welding.

Welding supplies are crucial for the best convenience and effective use of time in addition to producing the best outcomes. Some welders also need equipment to work, such as grounding clamps and replaceable electrodes. You won’t be able to carry out simple tasks without these items.

Must-Have welding tools and welding accessories

1. Auto-Darkening Welding Helmet

Auto-Darkening Welding Helmet is one of the must-have welding tools and accessories. It is an essential and must-have item for any welder to ensure safety during the welding process. It helps shield your face from sparks and flames and guards against heat damage to your skin and eyes.

It also has the additional benefit of shielding your eyes from the glaring glare produced by other welding equipment and the heated metal itself. You can readily view the workpiece before beginning the weld with the Auto-Darkening Welding Helmet, which results in greater accuracy and decreased frustration.

2. Safety Glasses

The eyes of the welder can be shielded from the high heat and optical radiation produced by welding by wearing safety glasses. For specific sorts of welding or cutting that don’t produce significant sparks, they can be used in place of a helmet. However, they simply serve as eye protection and are not full visors.

3. Welding Gloves

Welding Gloves are shielded from the intense heat by wearing thick gloves with a heat-resistant liner. This is one of the indispensable essential welding tools and welding accessories.

There are welding gloves that are so thick that you can pick up hot metal objects without getting burned in a matter of seconds. For TIG welding, there are even thinner gloves available if you need to handle the torch more precisely.

4. Welding Boots

Welding with sparks that cover a large region. Your feet are the closest object to a fire that might cause damage, and you can get burned very quickly. Sparks or droplets of molten metal won’t harm safety shoes. Thus, it aids in preventing burns to the skin.

Additionally, these are sturdy shoes with superb support and steel in the toe to shield your toes from any heavy objects that may fall.

When welding metal or steel, workers are exposed to electric shock and sparks. Casual footwear, such as leather or rubber shoes, might therefore overheat and raise the risk of additional risk factors.

The best footwear to wear when working in these environments is non-conductive footwear or antistatic boots. Wearing safety shoes helps to lower risk factors and shields your feet from sparks.

5. Welding Jacket

Wearing a welding jacket while working will shield your entire upper body from the extreme heat, UV rays, and welding spatter. However, make sure your jacket has a button-down collar, long sleeves, and is fireproof.

You must take extra care to prevent hot metal shards from entering your body and arms in addition to safeguarding them from the outside elements. Leather, wool, and denim are some of the strongest materials.

6. Welding Magnets

For welders, welding magnets are incredibly helpful since they allow you to hold metal components in place without requiring clamps and are simple to use. Additionally, you can use them to join metal components and weld them at an angle to one another.

Because of their versatility, it is a crucial welding fabrication equipment. Minor to large welding tasks, they are available in a range of sizes. You can simplify your task by purchasing more magnets.

7. Welding Clamps

Welding To keep substantial metal parts together when welding them together, clamps are often used in conjunction with clamp locks. They are well-liked for numerous hardware welding projects, beyond merely soldering, because they can simultaneously exert pressure from above and below.

When using Clamp C, turn the screw through the clamp’s frame’s bottom until the desired amount of pressure is generated to hold the workpiece. When the clamp is tightened, the fixed workpiece is held in place by the flat ends of the screw and the flat end of the frame.

In comparison to pinch clamp and even some soldering clamps, c-clamp also enable more pressure to be generated, resulting in a far more reliable grip on the object you need to clamp. Metal warping from welding would cause your projects to be off-square if these clamps weren’t holding your workpieces together.

8. Welding Pliers

They can be used as hammer, to install nozzles and heads, cut wires, clean nozzles, and remove solder. Any circumstance may benefit from the use of soldering pliers. They are quite useful for clearing faucet splashes and enhancing air movement.

Most hardware stores carry welding pliers, and you can also buy them online. They don’t require specific skills to use, and the price is reasonable considering what you can create.

9. Chipping Hammer

To clean up welding slag and debris from the weld face, use a chipping hammer. A chipping hammer can be used to remove them, and every welder needs to keep a particular kind of hammer on hand.

The flat face and pointed side of the chipping hammer are designed for various forms of metal. Even though you might not use them frequently, they help to make soldering easier to control and cleaner.

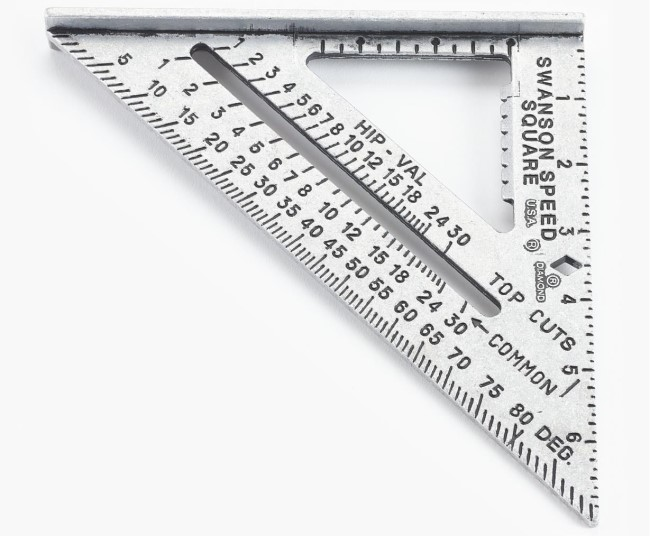

10. Speed Square

You probably use the speed square more than any other tool on this list. Any piece can be measured perpendicular to another piece to cut at a 90° angle or at any angle other than the square of your speed. When you need to be really accurate, this tool comes in handy.

An angle measuring tool in the shape of a right triangle, the Speed Square enables a range of measurements at various angles. You’ll discover that you need to utilize this soldering tool the most out of all the others. You can’t do much if you can’t quantify it.

11. Metal Brush

If you’re welding with a method that generates slag, you need a metal brush. You must scrape off the layer if you’re using a stick or flux arc welder to weld in order to see the finished product.

The best tools for this are chipping hammers and metal brushes. Due to its shielding properties, this coating is produced during welding. Protecting the weld pool from contaminating air is necessary.

Slag is only produced during some welding processes, specifically those that call for the use of both a metal brush and a hammer.

12. Welding Framing Jig

The Welding Framing Jig provides a tool that enables welding at a 90-degree angle. While soldering magnets can be used for this, framing jigs allow for far larger levels of support during welding and permit the use of heavier pieces of metal.

In addition, it enables simultaneous soldering of numerous layers or components at a perfect 90-degree angle, which is not possible with magnets.

13. Welding Table or Cart

Although it is used to transport other tools, the welding cart is not a tool itself. A welding cart must be used to transport bulky equipment like fuel and gas tanks. All of this can be moved more quickly and effectively using welding carts.

For the welder to be set at the proper height for them, there needs to be a firm surface. There’s a good possibility you’ll have a set table if you’re in a store. To make moving your vehicle with welding easier, you’ll need a robust cart with wheels.

A toolbox is sometimes included with welders, providing you with a convenient place to store everything else.

Frequently asked questions (Weld FAQ)

Are welding accessories really necessary for me?

Yes, it is really necessary and very important in your welding process. With the help of welding accessories, you may work more safely, efficiently, and effectively in general.

In addition to the above must-have accessories, what else can I buy?

Depending on your needs and work, what you are equipped with to ensure your safety and convenience. You can use welding knee pads, welding respirator; or hand tools like grinder angle, hacksaw, hand file,… In addition, there are marking and measuring tools such as soapstone, permanent markers, sheet metal gauge,…

Final words

When performed incorrectly, welds can be harmful to the welder because it is a dangerous operation. Workers need to be protected from any potential hazards, which is why safety equipment is crucial. As a result, quality welding tools can enhance safety, make it easier for you to complete the task, and enhance your work in general.

Learn more: What is a Welding Machine? What Types are Popular today? Uses of Each Type?