Cold TIG welding machine is an indispensable machine in industries, construction and especially mechanical engineering. However, not everyone knows about its structure and working principles. Let’s learn about cold TIG welding machines with us through the post “Cold TIG welder definition, When Using Cold TIG welding machines” below:

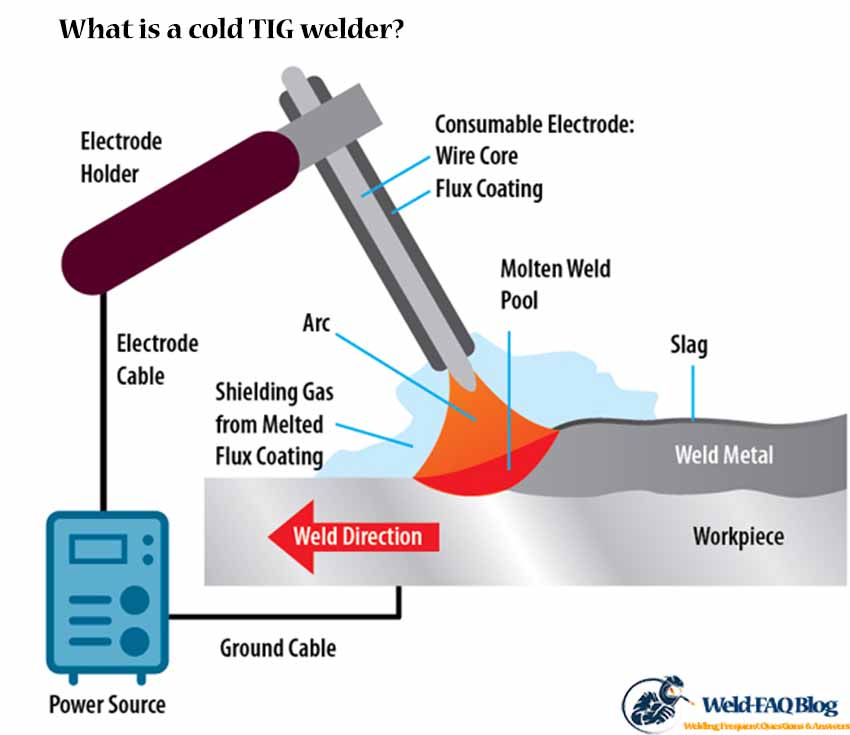

What is a cold TIG welder?

Cold TIG welding machine is a welding machine that uses a non-molten tungsten electrode. This electrode is only used to maintain the arc, generate heat to melt the welding consumable and the external welding rod. The entire weld, arc, electrode and consumable are covered with an inert gas, usually argon or helium. Solder wire must therefore be clamped together with the gas bellows, connected to the inert gas cylinder. Due to the use of an inert gas environment, the metal is not oxidized, so there is no need to use solder.

Classification of cold TIG welding machines

TIG cold welding machines are available in both DC and AC models. Welding machines are designed specifically for different purposes depending on the welding material and the required arc characteristics.

-Direct current (DC): DC current will have two types of wiring, forward-biased and reverse-biased (according to the convention in arc welding). However, reverse polarity is rarely used in TIG welding because this type of wiring has the disadvantages of unstable arc, poor penetration depth and fast electrode wear. The only advantage of this method is the cleaning effect of the oxide layer on the surface of the material, which works well when welding easily oxidized metals such as aluminum and magnesium. However, most other metals do not need this process, so in TIG welding mainly uses the forward bias method. Forward polarization is a more stable arc, a better penetration depth than reverse bias, resulting in less stress and distortion of the weld.

Alternating Current (AC): is a combination of both forward and reverse bias. Therefore, when in the reverse polarization half-cycle, it also has the effect of removing the oxide layer on the surface. Therefore, when welding metals such as aluminum, magnesium and beryllium copper, it is often preferred to use AC current over reverse bias DC current because with these metals, surface oxide removal plays a very important role. so that nice and clean welds can be obtained.

– DC welding machines often use a high-frequency current to cause the initial arc (called high-frequency supplement), and for AC welding machines, this high-frequency current is maintained continuously. Conventional TIG welding machines all operate in the current range of 3A to 350A, with voltages from 10V to 35V and a load factor of 60%. High-frequency welding machines can be used with conventional AC and DC power sources. AC power must have a minimum no-load voltage of 75V.

Advantages of cold welding

- High productivity.

- Low cost.

- Low welding energy, less thermal distortion.

- Welds most metals.

- Easy to automate.

- Long welds can be made without interruption.

- Requires low soldering skills.

Note when using cold TIG welding machines

To use the cold TIG welding machine optimally, the welder needs to fully prepare the following main tools:

- The mask protects the face, skin and eyes from the harmful effects of ultraviolet rays that damage the skin, infrared rays that damage the eyes, and at the same time to prevent sparks from the welding rod and the solder to be thrown into space.

- Gloves and clothes are made of leather or fabric separately to ensure work safety.

- Use shielding measures to avoid radiation reflections that affect the health of people near the welding place.

- Prepare ventilation equipment.

- Fully check the power cable.

- Welding pliers for electrode pairing

- The coupler is connected to the solder to communicate current with the solder (also known as ground contact).

Hopefully, the above sharing will help you gain more understanding about cold TIG welding machines, an overview of popular welding and cutting machines, as well as how to distinguish these types of machines. If you have a need to buy genuine welding and cutting machines with a warranty, please pay attention to buying equipment from reputable suppliers. You can visit Weldfaq to learn more and get more advice and Welding Frequent Questions & Answers.