For professional welders, having the right welding machine is essential for achieving high-quality welds efficiently and effectively. With a multitude of options available on the market, selecting the best welding machine can be a daunting task. In this article, we will explore everything you need to know about choosing the best welding machine for professionals. From understanding the different types of welding machines to evaluating key features and considerations, we will provide a comprehensive guide to help you make an informed decision and enhance your welding capabilities.

Choosing the Best Welding Machine for Professionals

Understanding Different Types of Welding Machines

Welding machines come in various types, each suited for specific welding processes. The most common types include:

a. Stick Welders (SMAW): Ideal for heavy-duty applications, stick welders use a consumable electrode coated in flux to create an arc and join metals.

b. MIG Welders (GMAW): Suitable for welding a variety of metals, MIG welders utilize a wire electrode and shielding gas to produce clean and efficient welds.

c. TIG Welders (GTAW): Known for their precision and versatility, TIG welders use a non-consumable tungsten electrode and filler material to create high-quality welds.

Considerations for Professional Welders

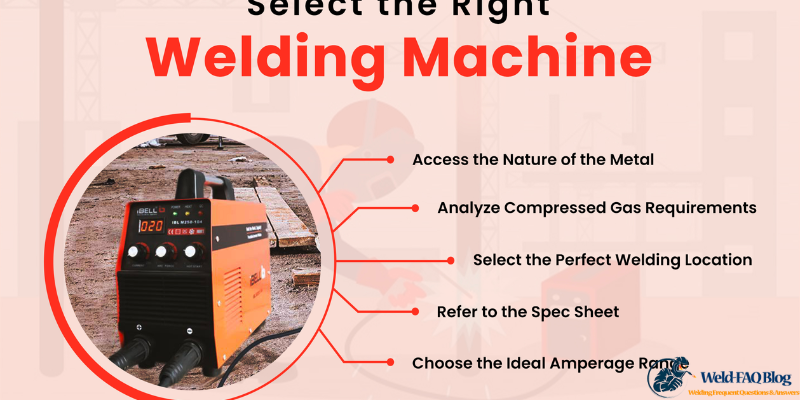

When choosing a welding machine for professional use, several factors should be considered:

a. Power Output: Assess the power requirements of your welding projects and select a machine with sufficient power output to handle the desired weld thickness and metal types.

b. Duty Cycle: The duty cycle indicates the amount of time a welding machine can operate continuously before it needs to cool down. Professional welders often require machines with higher duty cycles to handle long welding sessions.

c. Portability: Depending on your work environment, portability may be crucial. Consider the weight, size, and mobility features of the welding machine to ensure ease of transport and maneuverability.

d. Advanced Features: Look for additional features such as adjustable voltage and amperage settings, digital displays, and multiple welding processes to enhance your welding precision and versatility.

Quality and Durability

Professional welders require welding machines that can withstand demanding work environments and deliver consistent performance. Invest in machines from reputable brands known for their quality and durability. Read customer reviews, seek recommendations from experienced welders, and assess warranty options to ensure long-term reliability.

Safety Considerations

Safety should be a top priority for professional welders. Look for welding machines with built-in safety features such as thermal overload protection, voltage fluctuation protection, and reliable grounding options. Additionally, consider investing in personal protective equipment (PPE) such as welding helmets, gloves, and protective clothing to ensure optimal safety during welding operations.

Budget Considerations

While quality and performance are essential, it’s important to consider your budget when selecting a welding machine. Determine your price range and seek machines that offer the best value for your investment. Compare prices, features, and customer reviews to find a welding machine that meets your professional needs while staying within your budget.

Popular Welding Machine Brands

Several well-established brands are renowned for producing reliable and high-performance welding machines suitable for professional welders. Some notable brands include Lincoln Electric, Miller Electric, ESAB, Hobart, and Everlast. Research the product offerings, customer satisfaction ratings, and available support services for each brand to make an informed choice.

Evaluating User-Friendly Controls and Interface

When choosing a welding machine for professional use, consider the ease of use and user-friendly controls. Look for machines with intuitive interfaces, clear displays, and accessible control knobs or buttons. A well-designed control panel can enhance your productivity and efficiency by allowing quick adjustments of welding parameters during the welding process.

Compatibility with Accessories and Consumables

Consider the availability and compatibility of accessories and consumables for the welding machine you choose. These include welding electrodes, wires, shielding gases, and torch consumables. Opt for machines that have a wide range of compatible consumables and accessories readily available in the market. This ensures that you have access to the necessary materials for your specific welding applications.

Customer Support and Service

Professional welders may encounter technical issues or require assistance with their welding machines. Consider the customer support and service provided by the manufacturer or distributor. Look for companies that offer reliable technical support, comprehensive user manuals, and accessible customer service channels. Prompt and knowledgeable support can save time and ensure that your welding machine operates smoothly.

Seek Recommendations and Expert Advice

Before making a final decision, seek recommendations and advice from experienced welders or industry professionals. They can provide valuable insights based on their firsthand experiences with different welding machines. Attend trade shows, workshops, or welding forums to network with professionals who can share their expertise and help you make an informed choice.

By considering factors such as welding machine types, power output, duty cycle, portability, safety features, quality, budget, user-friendliness, accessory compatibility, and customer support, you can select the best welding machine for your professional needs. Investing in a reliable and high-performance welding machine will enhance your welding capabilities and contribute to your success as a professional welder.

Conclusion

Choosing the best welding machine for professional use requires careful evaluation of various factors. By understanding the different types of welding machines, considering power output, duty cycle, portability, safety features, quality, budget, user-friendliness, accessory compatibility, and customer support, professional welders can make an informed decision. By selecting the right welding machine, welders can achieve high-quality welds efficiently and effectively, enhancing their productivity and ensuring optimal performance.