Tools used for welding are referred to as welding tools since they must be used in order to complete the welding task. There are many different kinds of Welding Machine Safety Equipment And Tools that are used when working with so much heat and so many pressured components that they may seem overpowering but can actually be quite dangerous. Despite the fact that there is little to fear. Here is a summary of some of the welding equipment that is used in the industry safely and effectively.

1. Welding Machine Safety Equipment And Tools: Auto-Darkening Welding Helmet

To shield the welder’s eyes from the damaging UV radiation produced during welding, an auto-darkening welding helmet has a lens that darkens quickly.

The more sophisticated auto-darkening helmets, which automatically change the shade from an inactive state (light) to an active one (dark) when an arc is initiated, are one alternative offered to welders. Thanks to quick-changing LCD (liquid crystal display) technology in the auto-darkening cartridges, these helmets offer continuous protection from hazardous light emissions and dim to the pre-selected shade in milliseconds.

2. Welding Machine Safety Equipment And Tools: Welding Gloves

You can avoid electric shock, flames, hot components, flying metal, and arc rays by using welding gloves. The first line of protection against the hand risks of welding and cutting is a good pair of gloves.

All welders and cutters must put on protective gloves while working, according to ANSI Standard Z49.1 (see Information Sources). Different gloves may be used for various processes. Here are some recommendations for choosing the right gloves for welding and cutting.

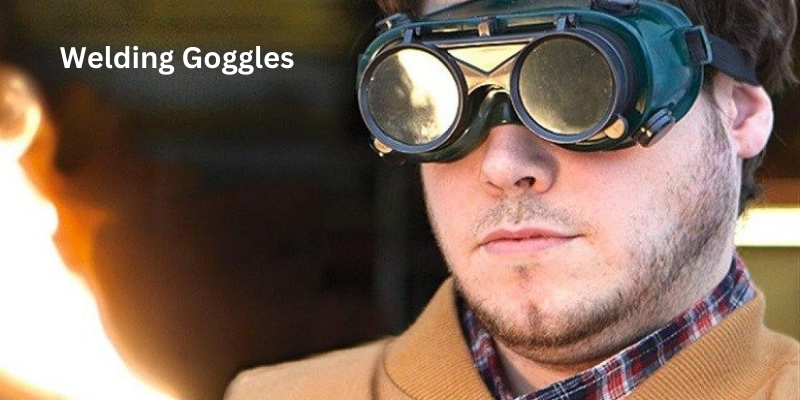

3. Welding Machine Safety Equipment And Tools: Welding Goggles

For some applications involving gas welding or oxygen cutting, welding goggles are made to offer protection. Welding goggles shield your eyes from powerful ultraviolet and infrared radiation in addition to heat and flying debris. Photokeratitis, a painful condition similar to suffering a severe sunburn of the cornea, can occur if suitable welding goggles are not worn.

4. Welding Machine Safety Equipment And Tools: Welding Magnets

“Arc wandering” will occur when welding close to a magnet. Anyone who disputes this should attempt it with some scrap steel. The magnet shouldn’t be placed in between them or moved in any other way, and your ground clamp should be as close as possible to the joint you are welding.

5. Welding Machine Safety Equipment And Tools: Hearing Protection

Hearing protection is used to lessen (attenuate) the amount of noise that reaches the wearer’s ears and, as a result, lower the possibility of hearing loss due to excessive noise. Hearing protection can lessen the audibility of warning sounds, but its usefulness is frequently constrained by environmental and occupational conditions. Due to these factors, hearing protection must be carefully chosen, worn, and is never a substitute for minimizing workplace noise.

6. Welding Machine Safety Equipment And Tools: Welding Framing Jig

A welder frame jig is considered to be a tool that is not as essential as the other items on this list, despite being one of the most well-known pieces of equipment to have.

The main duty of a welder framing jig is to provide a tool for welding at a 90-degree angle. The use of a frame jig, which offers a significantly better degree of support during the welding process and enables the use of heavier metal components, is also identified in the event that a welding magnet might be used for this purpose.

7. Welding Machine Safety Equipment And Tools: Welding Respirator

During the welding process, a residue known as welding fumes is created. These fumes are composed of incredibly small and dense metal oxide particles. The strength of the weld fumes depends on a number of factors, including the type of welding employed and the composition of the material being welded.

The best cure is to put on a welding respirator as a safety precaution. The best welding respirator should be chosen by all welders, whether they are experts or beginners. There are already many different designs to pick from to change the amount of smoke in the office.

8. Welding Machine Safety Equipment And Tools: MIG Welding Pliers

MIG welding pliers are one of those items of welding equipment that are conveniently available in most hardware stores as well as online. When compared to other tools, these pliers are reasonably priced and seem to be everyday things.

They can be utilized for a variety of purposes, including: Nozzle removal from MIG gun – It is found that they are equipped with circular clamps that seem appropriate for removing the nozzle from the MIG gun. This contact tip is often used since it wears out quickly and can be loosened and tightened. Instead of utilizing a separate wire cutter, use the Cut 1/4″ Stick-Out option to save time.

The tips of pliers and spatter can be used to quickly clean the interior of the nozzle.

9. Welding Machine Safety Equipment And Tools: Welding Sleeves

Welding sleeves are referred to as those tools that fall into the same category as welding boots since they are crucial to your safety while welding but are not frequently discussed. Welding sleeves are known for having detachable sleeves and for being made of leather or another tough, flame-resistant fabric to protect your skin and clothing.

Most welding sleeves are normally attached to an apron with their own suspenders so they stay in place while welding. Others have what looks to be a collar that is connected to the sleeves for further comfort and security.

10. Welding Machine Safety Equipment And Tools: Welding Boots

Foot injuries are among the occupational accidents that happen most frequently yet are rarely discussed when working on such locations. According to estimates, 25% of all disability claims involve foot injuries incurred while working.

It’s crucial to protect your feet from hot metal and any possible heavy equipment during welding. Any pair of welding boots must be as robust as possible. Steel-reinforced toes and sturdy leather are required. Your feet are protected from molten metal dropping on them by the boots.

Conclusion

You can be asked to use extra, more specific items by your job or group. Everything possible is being done to ensure your safety and the safety of those around you. While welding, the welder and those nearby could be in risk. As a result, it’s essential that the welder is aware of the dangers and risks involved with welding as well as the safety precautions that can be taken.

Welding machine safety tools and equipment have been used as a method of risk and hazard prevention. To begin with, complete safety clothing and equipment should be used during all welding activities.